Setting

Alarms

Setting

Alarms| You can set alarm limits, configure alarm actions

and turn alarms on and off via the setup

dialog. |

|

| Any user can view the current alarm settings, but to make changes, you must first be logged in as a Supervisor. |  |

Accessing the Alarms Setup Page

From the home screen or the main run-screen, in monitor-mode or run-mode, press the setup button, then select the alarms icon.

This

takes you to the alarms setup page.

This

takes you to the alarms setup page.From here you can:

- View the Alarm Panel where you can see which zones are registering an alarm.

- View the Alarm Setup Panel where you can see the current alarm values and limits, and make changes.

- View and change the Alarm Actions to be taken by the controller in the event of an alarm condition being detected.

- View the Alarm Log.

- Change alarm settings and actions for the water-zones, if fitted.

Types of Alarm

The controller is able to detect the following alarms:

- Open Thermocouple (manifolds only). The controller cannot read a zone's temperature.

- Reversed Thermocouple (manifolds only). The temperature readings from the zone are incorrect.

- Cold Thermocouple (manifolds only). The temperature readings from the zone are incorrectly lower than the actual temperature.

- No-Load. The zone's heater (or connection to it) is faulty,

- Temperature Tolerance (manifolds only). The zone's temperature has drifted beyond a set amount from the setpoint.

- Power Tolerance (cavities only). The zone's heater is drawing more (or less) than a set amount of power than the average power drawn by the cavities.

- Tool Motion. Controllers fitted with a machine interface can detect when the tool is moving. This alarm can be set to trigger when a minimum number of movements is not detected.

Alarm

Setup

Alarm

SetupTemperature-Tolerance, Power-Tolerance and Cold-Thermocouple alarms are controlled by values set by a Supervisor.

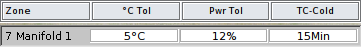

The Alarm Setup Panel displays a list of zones, identified by number and name (if configured).

The current value for each alarm condition is displayed for each zone in a table.

With a 12% power-tolerance, the zone will trigger an alarm if it's average power consumption for it's heater is 12% greater or less than the average power consumption for all of the cavities. You cannot set a power-tolerance for manifolds. The average is taken from the last 60 seconds, on a rolling-average basis.

A 15 minute cold-thermocouple detection time means that the controller expects the zone to reach setpoint within 15 minutes of starting up.

Edit Alarms

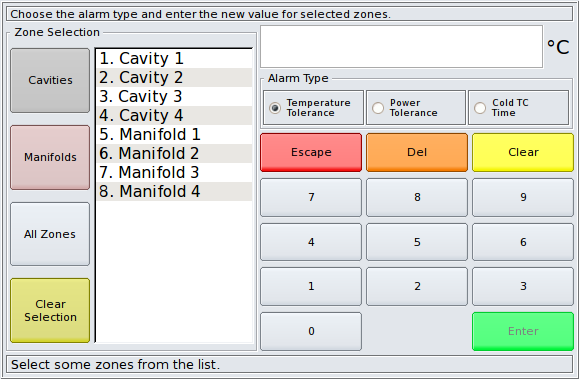

Edit AlarmsChanges to the temperature-tolerance, power-tolerance or cold-thermocouple alarm limits are made through the Edit Alarm dialog.

Using the Edit Alarm dialog is easy:

- Select some zones from the list. You can select zones in any order you wish. The list is populated with the zone number and the zone name, if one is configured.

- You can use the quick-select buttons on the lefthand side to quickly select all cavities, all manifolds, or all zones, or you can cancel your selection.

- Choose the alarm type you want to change for the selected zones.

- Enter the new value.

- For temperature-tolerance alarms, the new value is entered in degrees. This defines a band of temperatures above and below setpoint which are 'safe' from alarms.

- For power-tolerance alarms, the new value is entered as a percentage. This defines a range of values above and below the average power for all cavities which are 'safe' from alarms.

- For cold-thermocouple alarms, the new value defines the expected warm-up time of the zone(s), in minutes.

Alarm Actions

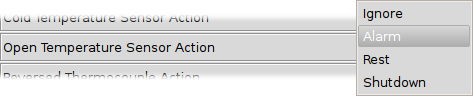

Alarm ActionsThe controller can take various actions when an alarm condition is triggered:

- Ignore. No action is taken.

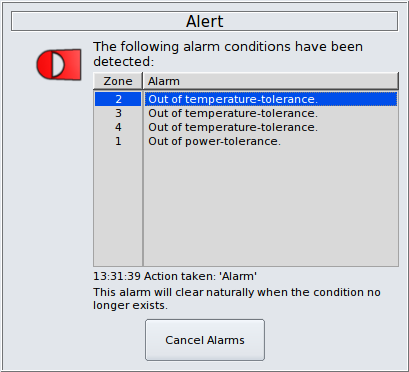

- Alarm. The controller toggles the Alarm relay, which if connected will sound the external machine alarm, start the alarm indicator lamp and stop the machine. The controller continues to maintain temperatures and the Alarm Warning Dialog is placed on the screen.

- Rest. All zones are placed into rest mode , the Alarm Relay is toggled and the Alarm Warning Dialog is placed on the screen.

- Shutdown. The controller turns all zones off, the Alarm Relay is toggled and the Alarm Warning Dialog is placed on the screen.

Spotting Alarms

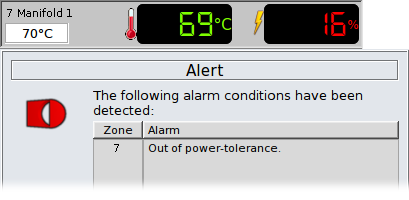

This

zone is out of temperature-tolerance (over setpoint), so it's

temperature is coloured red. If a temperature is coloured blue, it is

under setpoint.

This

zone is out of temperature-tolerance (over setpoint), so it's

temperature is coloured red. If a temperature is coloured blue, it is

under setpoint.Temperatures displayed in green are in-tolerance.

The zone is also out of power-tolerance (over); it's power level is coloured red. This zone needs more power than expected in order to maintain setpoint. If the zone needed less power than expected it would be coloured blue. Zones which are in power-tolerance are coloured yellow.

These colourings hold true so long as the zone has a configured value in it's Alarm Setup Panel (i.e.: it is not set to "off"), even if the Alarm Action is set to "ignore".

If an alarm action is set to any setting other than "ignore", the Alarm Warning Dialog will be displayed and the Alarm Relay will be toggled. Alarms actions set to "Alarm" will be removed from the Alarm Warning Dialog when the alarm condition no longer exists. When all alarms have been removed from the list, the Alarm Warning Dialog will be dismissed automatically, the Alarm relay will be toggled and the controller will resume normal operation.

However, if an alarm action is set to "Rest" or "Shutdown", the Alarm Warning Dialog will remain on-screen. The alarm conditions for these cases are not removed from the list and the controller will require user intervention in order to resume normal operation.

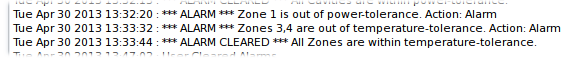

All alarm conditions are logged so you can see which alarms occured and when they were triggered:

You can check whether the Alarm Relay has been toggled from the status bar. An orange alarm-bell icon is displayed whenever there is an alarm and the alarm relay has been set to stop the machine from cycling: